„With virtual commissioning (VC), the sequential correctness of a material inlet can be tested in a simple simulation model for concept evaluation at an early stage of development. Good process can be tested in a simple simulation model. Neither a performance test nor a test for malfunctions and the malfunction behavior of the failure behavior of the plant is possible.“

Projects

The following projects show use cases based on the Digital Miniature Factory in the subject area of virtual commissioning as the results of scientific work by students of the FH Technikum Wien.

Comparison of VC simulation models (Visual Components)

In this thesis, three different simulation models of VC are compared on the basis of the storage of DMF. With the results of this master thesis a guideline could be created, which contains recommendations for different use cases of the simulation models.

Please accept cookies for external media to view videos

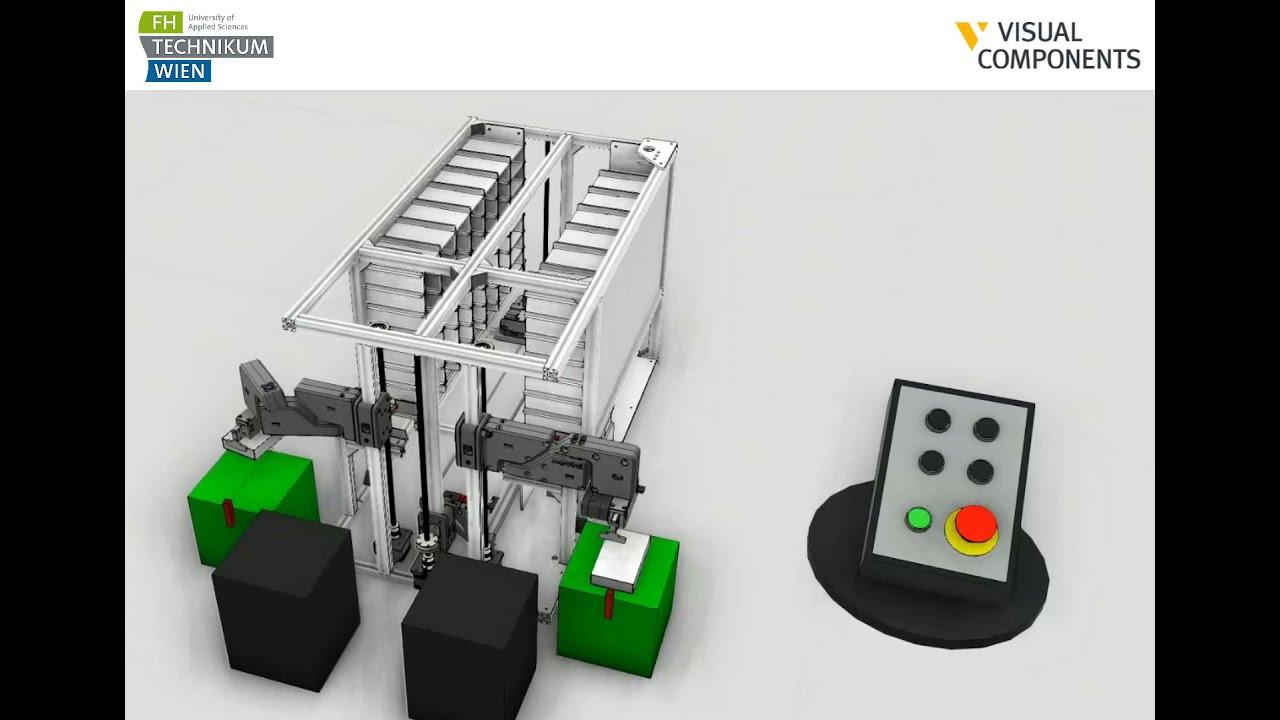

Virtual commissioning of a storage station (IndustrialPhysics)

The DMF storage station was put into operation virtually using IndustrialPhysics. The motion sequences are implemented by means of a sequence control and controlled by a pushbutton box. The project enabled optimization potentials to be identified with regard to the design of the hardware.

Please accept cookies for external media to view videos

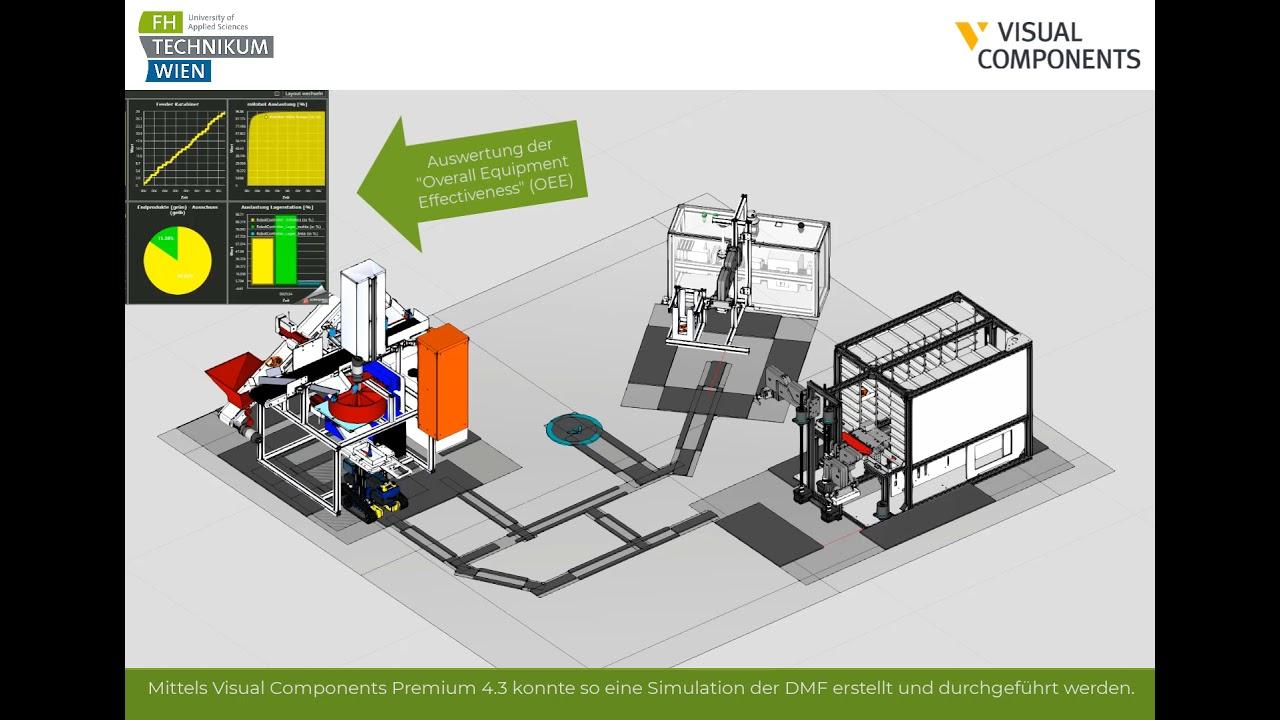

Layout optimization of a production line (Visual Components)

In this work, a process model of DMF is created. With the model, different layouts (placements of the stations) are investigated and evaluated. From this, the most suitable layout can be found, which enables the highest plant efficiency.

Please accept cookies for external media to view videos

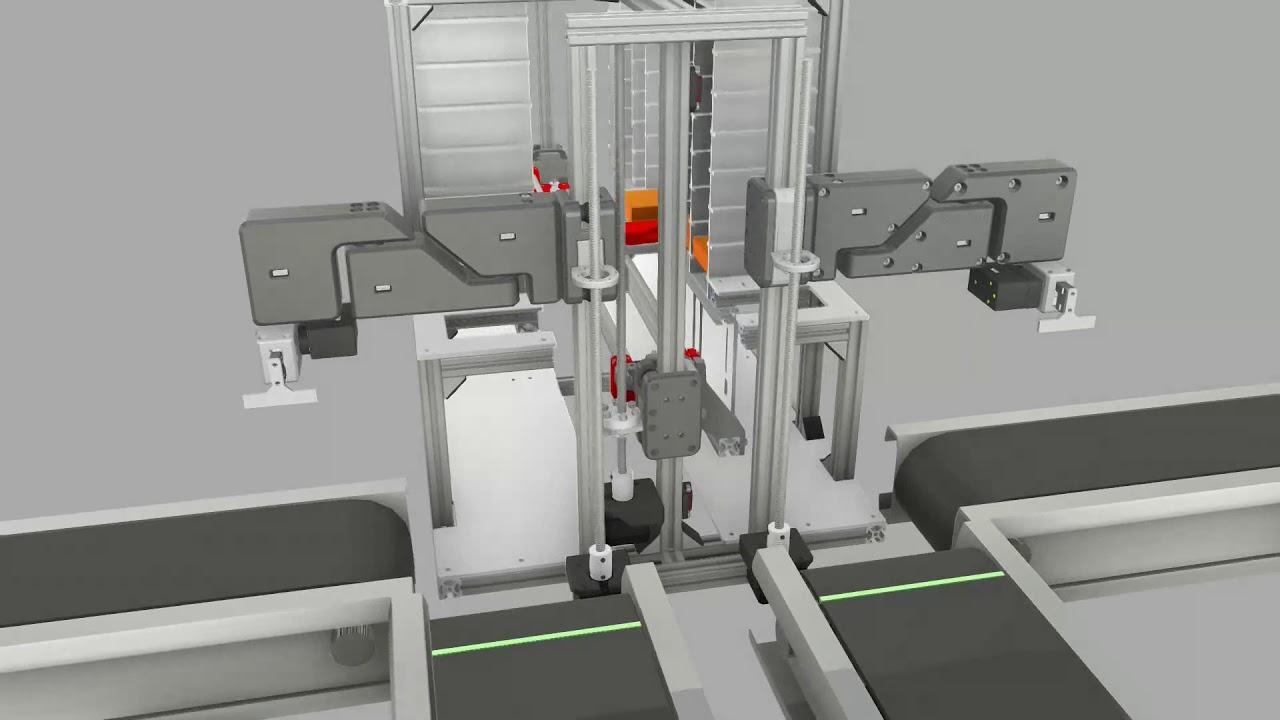

Virtual commissioning of a storage (Visual Components)

In this work, a VC of the storage of the DMF is implemented using Visual Components. Using the model-in-the-loop (MIL) method, a continuous motion sequence was realized. Thus, optimization potentials regarding design, cycle times and programming could be determined.

Please accept cookies for external media to view videos